When the "plastic restriction order" becomes "a piece of paper"

Release time:

2022-09-29 10:51

Source:

A survey of marine debris by the Hong Kong branch of the World Wide Fund for Nature (WWF) found that plastics account for an average of about 60% of the debris in mangroves, beaches, mudflats, and even in the undersea environment. The British "Guardian" reported that there are more than 5 trillion plastic debris floating in the ocean. Plastic - dubbed "the worst invention of the 20th century" is harming human health around the world.

As far as China is concerned, it has been seven years since my country implemented the "plastic restriction order" in 2008, which is like "a piece of paper". On the difficult road of plastic restriction, plastic machine enterprises play an irreplaceable role. Faced with severe environmental problems, plastic machinery companies shoulder heavy responsibilities from production to recycling.

Plastic bottle recycling is not ideal? Control the use of plastic production materials

In the past, we neglected that the disposal of plastic waste should start at the source. Perhaps we can compare "plastic restriction" with "plastic ban". "Plastic ban" is a measure that considers the source, but it is difficult to implement. Here, we start with how plastic machine companies can reduce the amount of material used.

The unsatisfactory recycling of plastic bottles is a major problem facing press companies at present. Some people suggest that companies need to improve the material and raw materials themselves, so as to achieve an increase in the recycling rate of plastic bottles of these materials.

For example, if a bottle produced by a plastics company weighs only 8.8 grams, the product controls the amount of material used, reduces resource consumption, and greatly reduces the impact of solid waste and greenhouse gas emissions on the environment. The product with a gram weight of 27.3 grams is more than three times the resource consumption and waste of a product with a weight of 8.8 grams, and the impact on the environment can be imagined.

The era of intelligent recycling: promoting energy conservation and environmental protection and the development and utilization of renewable energy

Plastic bottle recycling "smart era" The recycling system has become a major trend in the global environmental protection industry. At present, domestic plastic bottle intelligent recycling machines have been put into use to provide convenience for the public and invisibly increase the consciousness of the public. Through the production and operation of intelligent PET bottle recycling machines, the recycled waste bottles are processed into recycled materials.

One of the most attractive aspects of recycling machines for consumers is that they are nearly double the price paid by informal waste channels. Consumers can get a stable income of 0.10 yuan for every PET bottle they put in. Ordinary waste recycling vendors pay an average of 0.06 yuan per bottle, depending on the fluctuation of oil prices.

It has proven to attract big-name manufacturers and governments. With the value-added plan and profitability, it is feasible, the enterprise can gain a firm foothold, and the road to environmental protection can go for a long time.

With the promotion of the Internet of Things intelligent recycling machine in the market, it will change the pattern of my country's renewable resource system and become the standard supporting equipment for intelligent solid waste treatment in public places in the planning and construction of China's smart cities in the future, and it will also become a "smart city" in China. one of the important symbols.

Starch plasticization technology returns plastic waste to nature

In all walks of life, technology is the soul of an enterprise, and so is a plastic machine enterprise. To successfully degrade plastic waste and return to nature, this cannot be accomplished by traditional methods, and must be achieved by technological research and development.

It is understood that a domestic independent plastic fully degradable bioplastic technology, a new technology of starch plasticization, has passed the appraisal of experts of the appraisal committee. This technology has solved the problem that traditional plastics are difficult to degrade and cannot be returned to nature. It is of revolutionary significance to the recycling and complete degradation of plastic products. It can be completely plasticized with common starch such as corn and cassava, and added with bentonite to make products that can completely replace the current general plastics.

After this technology is fully promoted in the press industry, it will play a revolutionary role in cracking down on the cause of plastic waste, and it will also make a great mark in history.

The "Plastic Ban" action started from the plastic machinery industry

The "plastic ban" has been implemented in China for 7 years, and freezing three feet is not a day's cold. To solve the problem of plastic waste, we must take steps to solve the problem of plastic waste. Optimize production methods and strive to attack the market of environmentally friendly plastics with minimal cost. I believe that a new turning point is getting closer and closer to us, and the plastics industry will then develop in a benign direction.

Related news

High-performance plastics are on the rise in China

The Chinese plastics industry is slowly but steadily shifting from a commodity-based model to an R&D and intellectual property-driven model. This is a major theme at the three-day China International Engineering Plastics Industry Innovation Conference. The conference was hosted by China Plastics Processing Industry Association and was held in Chongqing in late September.

Liquid material with porous structure emerges

An international joint research team has announced that they have synthesized the world's first liquid material with a permanent porous structure. This liquid has a strong ability to absorb and dissolve gases, which is expected to improve the reaction efficiency of many current chemical reactions and be applied in scenarios such as carbon capture. The related paper was published in the journal "Nature" published on the 12th.

Plasticizers have never gone far, involving all kinds of daily consumer goods

Compared with Europe and the United States, the research on the standard and scope of plasticizers in my country is still lagging behind. my country has only given migration limits for 3 species, while the EU has given migration limits for 7 species. The regulation of plasticizers needs to establish standards as soon as possible and catch up.

When the "plastic restriction order" becomes "a piece of paper"

A survey of marine debris by the Hong Kong branch of the World Wide Fund for Nature (WWF) found that plastics account for an average of about 60% of the debris in mangroves, beaches, mudflats, and even in the undersea environment. The British "Guardian" reported that there are more than 5 trillion plastic debris floating in the ocean. Plastic - dubbed "the worst invention of the 20th century" is harming human health around the world.

High-performance plastics are on the rise in China

The Chinese plastics industry is slowly but steadily shifting from a commodity-based model to an R&D and intellectual property-driven model. This is a major theme at the three-day China International Engineering Plastics Industry Innovation Conference. The conference was hosted by China Plastics Processing Industry Association and was held in Chongqing in late September.

Material compression molding principle

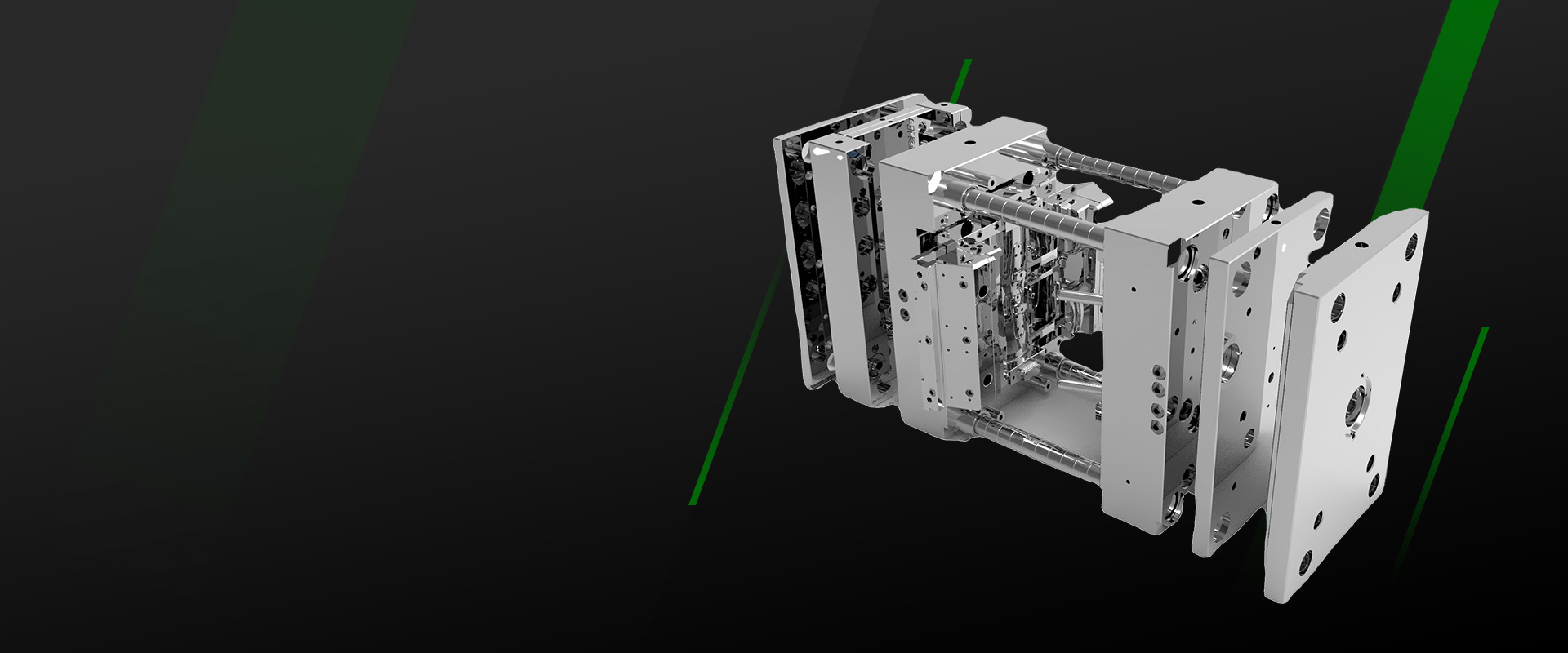

Product material pressing refers to the process in which the molding material is plasticized under the action of hot pressing, and fills the mold cavity to solidify and form. When the material is added to the mold and heated, the resin softens and melts, making the molding material fluid, and begins to flow and fill the mold cavity under the pressure of the press.

Wechat/Whatapp

+8613509006811 (SKYPE:jennywang991)

+8613556692652

ADD

No. 2, Kanghua Road, Tanxi, Shipai Town, Dongguan, Guangdong