High-performance plastics are on the rise in China

Release time:

2022-09-29 10:51

Source:

The Chinese plastics industry is slowly but steadily shifting from a commodity-based model to an R&D and intellectual property-driven model.

This is a major theme at the three-day China International Engineering Plastics Industry Innovation Conference. The conference was hosted by China Plastics Processing Industry Association and was held in Chongqing in late September.

The participants of the conference included not only many well-known multinational companies, but also up-and-coming local enterprises in the field of domestic engineering plastics.

Ivo Lansbergen, president of DSM Engineering Plastics Asia Pacific, told Plastics News that the demand for engineering plastics will only increase in the future. "If you want to improve fuel efficiency, it's best to make sure the engine compartment is warmer. It burns better. And if the temperature goes up, you need materials that can withstand high temperatures," he said.

Surface-mount technology, which is widely used in today's ultra-thin, ultra-light consumer electronics industry, also requires the use of plastics that can withstand high temperatures, Lansbergen said. "You can't use normal resins or polymers anymore. You need polymers that can withstand these [higher] temperatures."

Among local companies interviewed by Plastics News, Chen Bo, R&D manager of Ningbo Nengzhiguang New Material Technology Co., Ltd., said the company had a turnover of 150 million yuan last year and was showing double-digit growth.

Bo Chen holds a PhD in polymer materials and is one of six PhDs in the company's team of more than 100 people.

Energy Light's nylon modifiers improve mechanical properties at high and low temperatures. Its polypropylene modification can reduce polypropylene volatility and target applications that require no odor, such as automotive interiors, medical supplies and food packaging. The company also produces halogen-free flame retardant additives for PE and EVA.

Like many domestic peers, Ningbo Nengzhiguang also targets overseas markets. "We export to India, Canada and Thailand. We just entered the UK market this year." However, exports are still in their infancy, accounting for only 5% of total sales.

Another domestic company focusing on high-performance nylon is Dongguan Eprowan Nylon Technology Co., Ltd., which was established in 2004. Liang Xiaoli, general manager of the company, said that last year's turnover of 50 million yuan came from domestic sales, mainly for the automotive and electronic markets.

Liang Xiaoli was interviewed by Plastics News through a translator after giving a speech on nylon parts for automobile engines. He is very optimistic about the future prospects of the company. "While growth in the auto industry has slowed, [sales volumes] are still huge," he said.

Nylon parts are faster and less expensive to produce than similar metal parts, he said.

He said Epone has a product that helps mix glass and nylon for high-temperature applications. "We're doing more research on nylon that's more durable and resistant to high temperatures," he said.

The conference also attracted a number of foreign companies, such as Polymer Asia, a Vietnamese masterbatch manufacturer.

Kim Quy Nguyen, general manager of the company, said: "We are here to understand the fast-growing Chinese market and grasp new technologies in the global engineering plastics field."

"Most of our customers are in Vietnam, but we also export to Indonesia, Malaysia, Singapore and Thailand. We started exporting to the US market last year," Nguyen said.

Founded in Ho Chi Minh City in 2002, Polymer Asia has annual sales of US$30 million and employs 170 people, Nguyen said.

The conference also hosted an innovation forum to discuss plastics machinery and plastics for the automotive and electronics industries.

High-level industry association officials from Taiwan, Japan, India, Italy and Russia attended the meeting. Michael Taylor, vice president of the American Plastics Industry Association, delivered a speech related to sustainability and innovation.

Related news

High-performance plastics are on the rise in China

The Chinese plastics industry is slowly but steadily shifting from a commodity-based model to an R&D and intellectual property-driven model. This is a major theme at the three-day China International Engineering Plastics Industry Innovation Conference. The conference was hosted by China Plastics Processing Industry Association and was held in Chongqing in late September.

Liquid material with porous structure emerges

An international joint research team has announced that they have synthesized the world's first liquid material with a permanent porous structure. This liquid has a strong ability to absorb and dissolve gases, which is expected to improve the reaction efficiency of many current chemical reactions and be applied in scenarios such as carbon capture. The related paper was published in the journal "Nature" published on the 12th.

Plasticizers have never gone far, involving all kinds of daily consumer goods

Compared with Europe and the United States, the research on the standard and scope of plasticizers in my country is still lagging behind. my country has only given migration limits for 3 species, while the EU has given migration limits for 7 species. The regulation of plasticizers needs to establish standards as soon as possible and catch up.

When the "plastic restriction order" becomes "a piece of paper"

A survey of marine debris by the Hong Kong branch of the World Wide Fund for Nature (WWF) found that plastics account for an average of about 60% of the debris in mangroves, beaches, mudflats, and even in the undersea environment. The British "Guardian" reported that there are more than 5 trillion plastic debris floating in the ocean. Plastic - dubbed "the worst invention of the 20th century" is harming human health around the world.

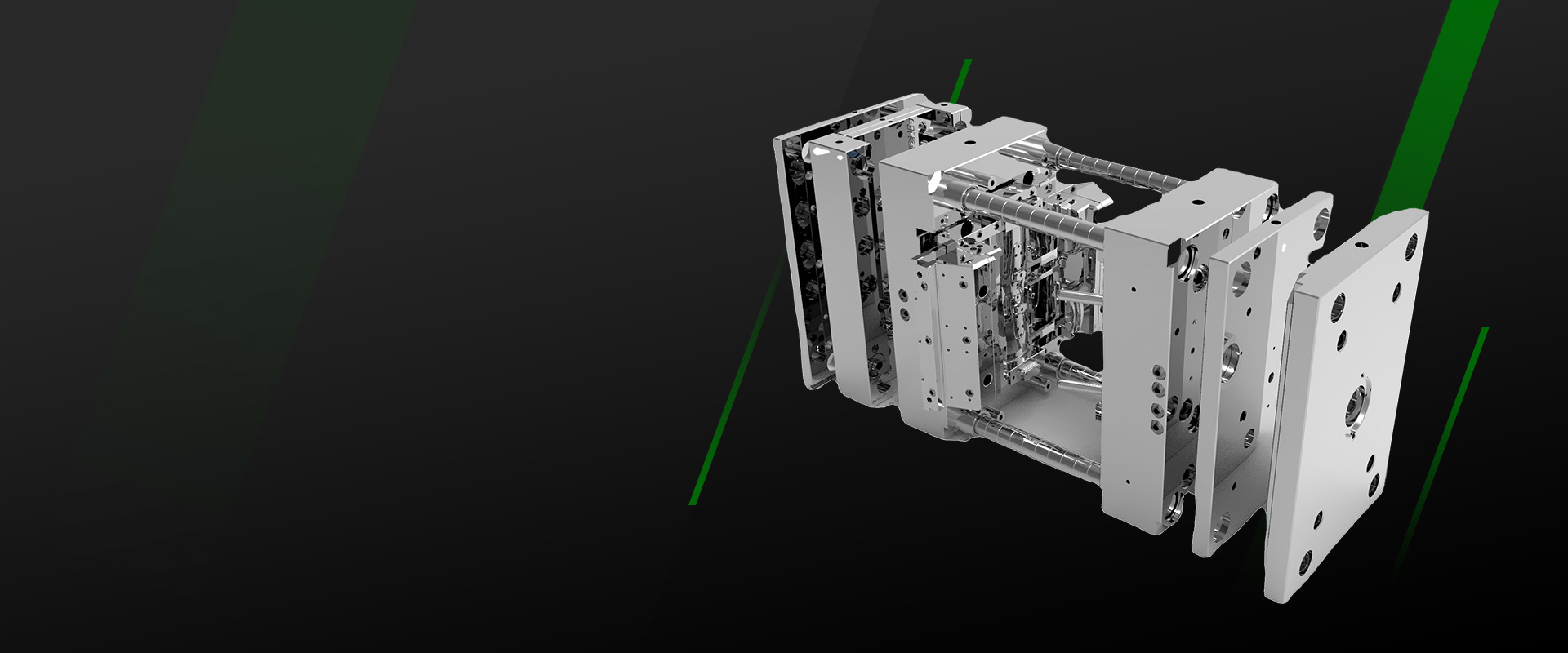

Material compression molding principle

Product material pressing refers to the process in which the molding material is plasticized under the action of hot pressing, and fills the mold cavity to solidify and form. When the material is added to the mold and heated, the resin softens and melts, making the molding material fluid, and begins to flow and fill the mold cavity under the pressure of the press.

Liquid material with porous structure emerges

An international joint research team has announced that they have synthesized the world's first liquid material with a permanent porous structure. This liquid has a strong ability to absorb and dissolve gases, which is expected to improve the reaction efficiency of many current chemical reactions and be applied in scenarios such as carbon capture. The related paper was published in the journal "Nature" published on the 12th.

Wechat/Whatapp

+8613509006811 (SKYPE:jennywang991)

+8613556692652

ADD

No. 2, Kanghua Road, Tanxi, Shipai Town, Dongguan, Guangdong